Who We Are

Emaar Platform is a one-stop marketplace for all businesses which seek to make the process of procurement of industrial pumps for varied industries. The Platform aims to optimize and reduce the time lag that occurs from the moment an RFQ is raised by a customer to the retailers/ distributors from the OEMs. The platform aims to use advanced prediction modeling based on the customer's specific industry to mitigate any logistical and procurement challenge that might cause a delay in the operations of the businesses.

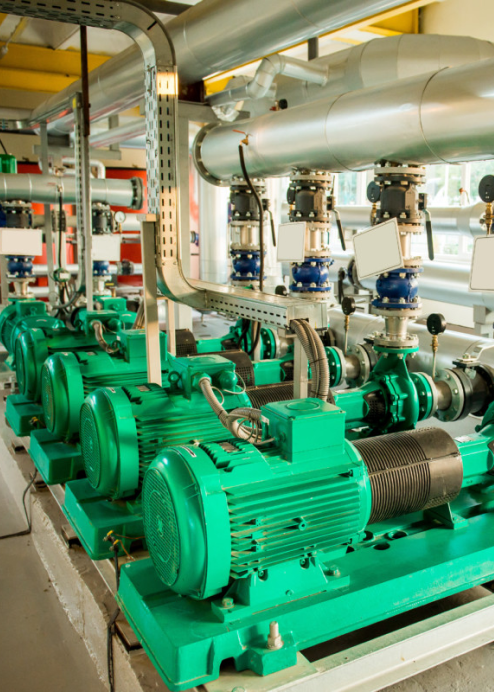

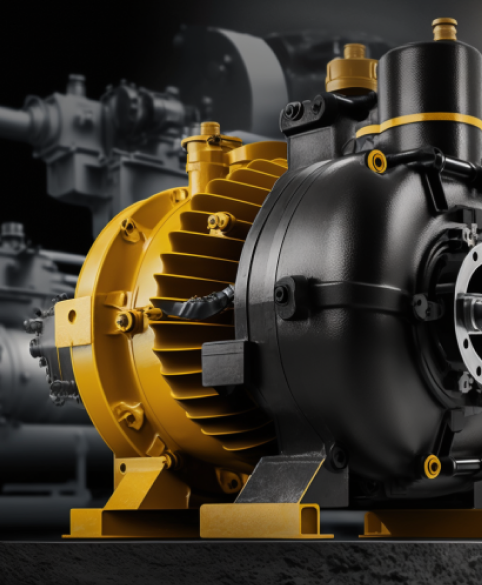

Our Products

Top brands we carry

Knowledge center on varied resources

Power Plant Industries

The pumps used in the power plant are divided into two major systems according to their functions: steam turbine auxiliary pumps, front pumps, condensate pumps),

Agriculture Industries

An agriculture pump helps you transfer water from one source to another with ease. Whether the source is underground or situated on the surface.

Oil and Gas Industries

Industrial pumps are essential devices required in every phase of oil and gas operations. Basically, they help transfer process fluids from one point to another.

Our Team

Muzaffar Mulla

CEO

Industry executive with a 20-year track record with a focus on delivering high-quality results and customer satisfaction.

Extensive experience in a variety of sectors, including pharmaceuticals, oil and gas, power, chemicals, and water treatment.

Vast knowledge in the areas of Pumps, Spare Parts, and other mechanical parts used in the Industry.

Chemical engineer with a keen interest in technology-driven business concepts.

Riyaz Rumaney

COO

Over 28 years of experience with expertise in design & detail engineering.

Excellent operational management and leadership skills, including expertise in setting up procedures and processes.

Skilled at establishing and expanding companies in the commercial and industrial sectors across a range of regions.

Mechanical engineer with a focus on plant design and piping for the oil, gas, and refinery sectors for over 24 years.